The toughest and most durable finishes that you can apply to a garage floor today is an epoxy or polyaspartic coating.

Http sunlitspaces com 2013 02 19 garage floor epoxy tips and tricks.

We also offer a complete selection of accessories and tools for coating applications.

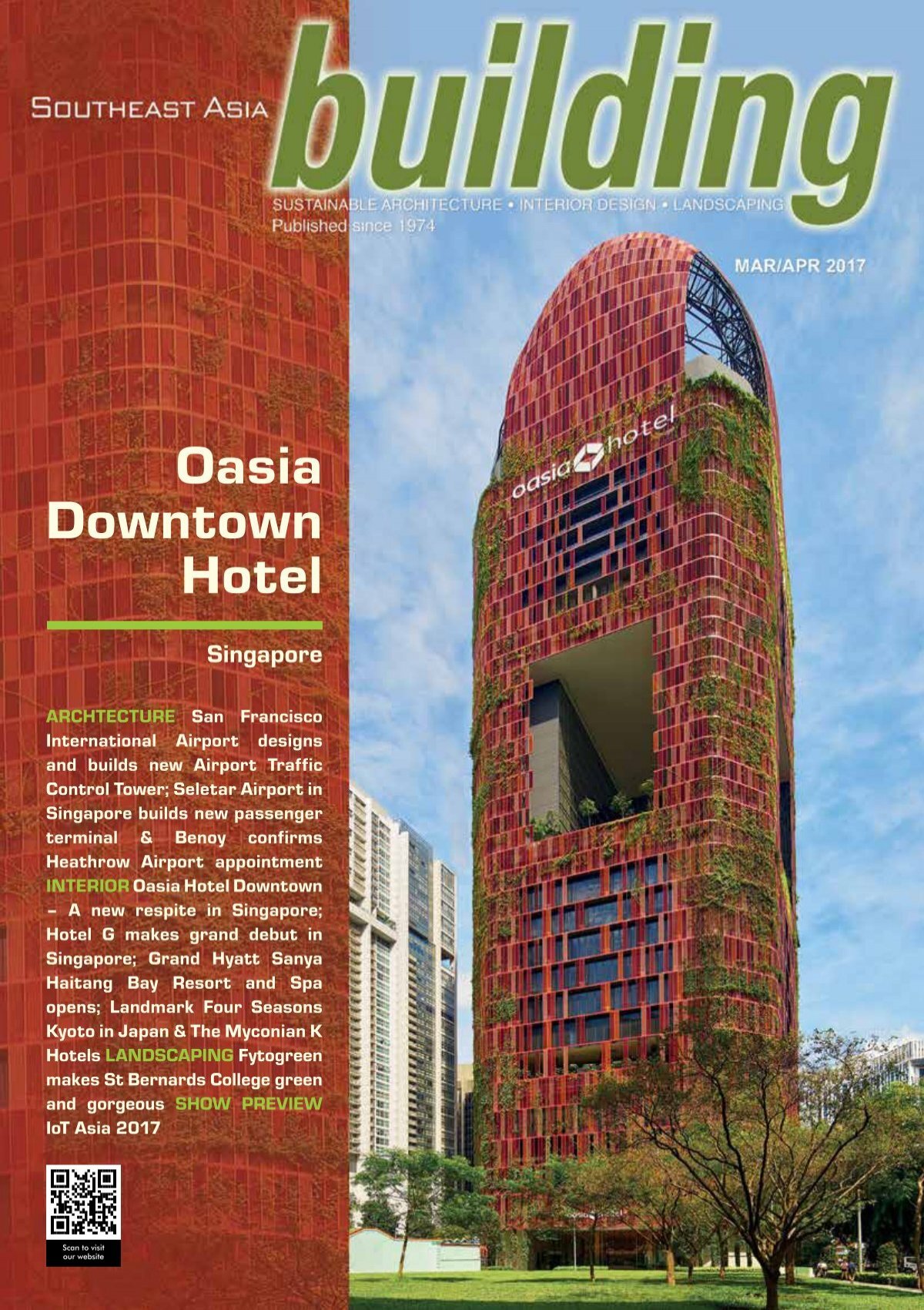

Many homeowners apply epoxy floor coatings in their garages to make them more durable and attractive.

Armor granite garage floor epoxy is 23 mils thick comes with 20 lbs of chips spiked soles and three coats of clear urethane fortified epoxy topcoat.

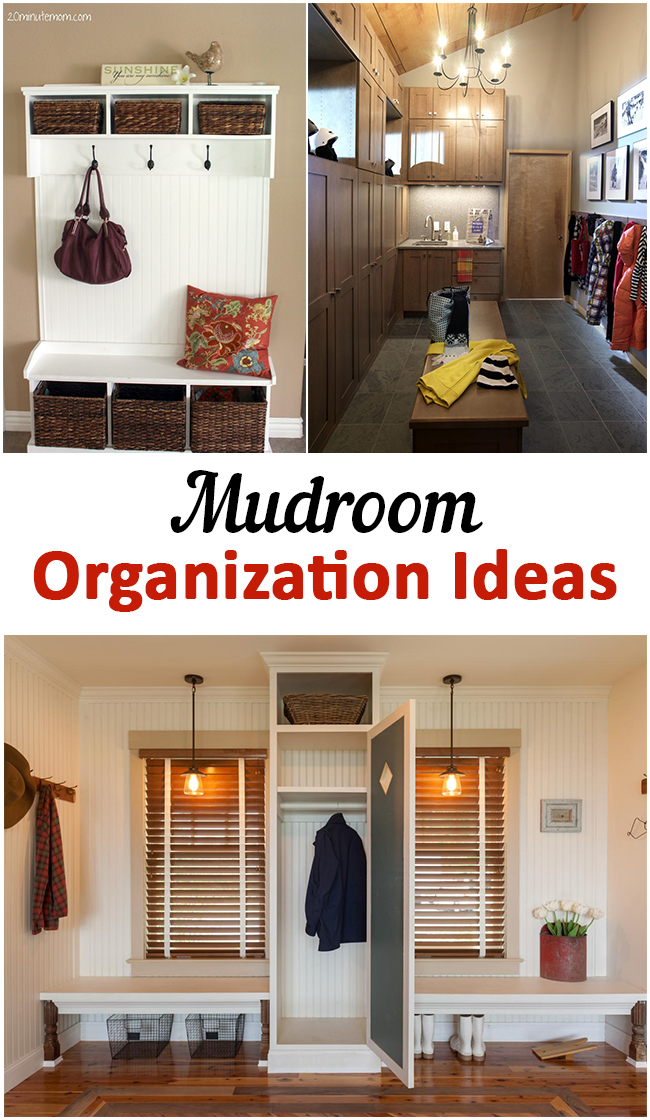

We learned a few tips tricks to share with you today.

Check out our best tips tricks to help you get it right.

Rust oleum rocksolid 2 part gunmetal high gloss garage floor polycuramine kit actual net contents.

Epoxy and polyaspartic flooring systems are hard abrasion resistant and have high impact strength.

Before you do use garage floor epoxy in your garage check out these tips to make a tricky job a little easier.

Kilz l377611 1 part epoxy acrylic interior exterior concrete and garage floor paint satin silver gray 1 gallon 1 gallon 4 l 4 4 out of 5 stars 600 32 98 32.

For pricing and availability.

It is definitely a good diy project.

This old house host kevin o connor assists epoxy coating expert doug fasching in creating a good looking hardwearing stain resistant garage floor.

Cannot be compared to home improvement store type epoxies.

You normally have to wait a few days before parking any vehicle on a newly coated floor.

Last summer we applied garage floor epoxy to the floor of our two car garage.

Epoxy floor coating gives a very unique and beautiful look to any room whether it s a garage or an exercise area.

It depends on what type of vehicle you will be parking on your new epoxy floor and what type of epoxy paint you used.

Armor chip garage floor epoxy is 19 mils thick comes with 8lbs of color chips and two coats of clear urethane epoxy topcoats.

If the epoxy coat has chipped away from some area or has faded away it can easily be coated with another layer of epoxy floor coating.

The reason being is that although the epoxy will be dry to the touch in about 8 10 hours the chemical curing process is still going on.