This video shows you how floor joists are joined together whether in a long continuous run or laid side by side the australian timber framing code suggest se.

How to tie floor joist together.

The longer the overlap distance the stronger the connection.

It utilizes an existing support structure but may require the opposite end of the new deck to be supported.

This video will provide.

In this case the rafter as a whole is actually stronger than it would have been because the splice is more than adequate and the plywood adds to the strength.

A day until they re level.

Then set new joists same height as existing ones alongside the old.

Simpson strong tie catalog specifications and simpson strong tie connectors are properly installed in accordance with applicable building codes.

Nailing two 2x4s together will work to span about three joists unless the sag is under a weight bearing wall.

Shall be limited at the discretion of simpson strong tie company inc to repair or replacement of the defective part.

It is important to jack this end level to keep the floor from sagging any more and to keep the joists from splintering later.

The amount of weight that each floor joist handles is pretty amazing.

Above we illustrated using steel framing connectors to tie i joists to a wall top plate and stud for the case of i joists that run on top of the building walls.

All warranty obligations of simpson strong tie company inc.

Sistering joists is commonly used when adding onto an existing deck or repairing a deck.

Tack a beam under the sagging joists.

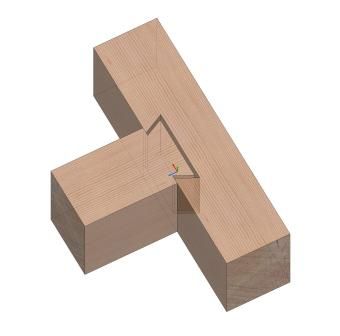

In these cases the overlapped joists help tie the framing together by combining the rigid members over a beam.

In this case the framer just needed a longer rafter.

And that leads to a wavy deck surface.

Simpson strong tie and other manufacturers provide straight for floors or angled i joist hangers for framing i joists between building walls such as for installation of a floor a.

Use narrower lumber 2x8 blocking on 2x10 joists so the blocking looks less conspicuous from a distance.

Also install diagonal blocking to keep the entire frame from racking.

You should overhang at least a couple of feet on each side of the beam.

Set a hydraulic jack and post under the beam and jack up the joists about 1 8 in.

To help keep joists flat always attach blocking perpendicular to the joists.