To add oil to a hydraulic floor jack start by making sure the jack is completely lowered by turning the jack s release valve counterclockwise until it s as low as it can get.

How to put oil into a floor jack.

How to put oil in a hydraulic floor jack.

In order for your floor jack to perform at optimum ability the oil needs to be filled and changed on a regular basis.

You hydraulic floor jack should be stored in the upright position at all times.

The most common problem user faced while filling the oil is not to follow the requisite oil mark.

Every time you finish using the hydraulic floor jack you should release the pressure and lower the arm.

Step 5 maintain filling procedures.

Doing so leads to more oil in the tank which leads to overflow.

After you have completely filled the hydraulic floor jack it is important that you replace the filler port cap so as to avoid any leaking from the jack.

This will ease up the tension in the floor jack and cause the oil to floor back into the reservoir to avoid contamination.

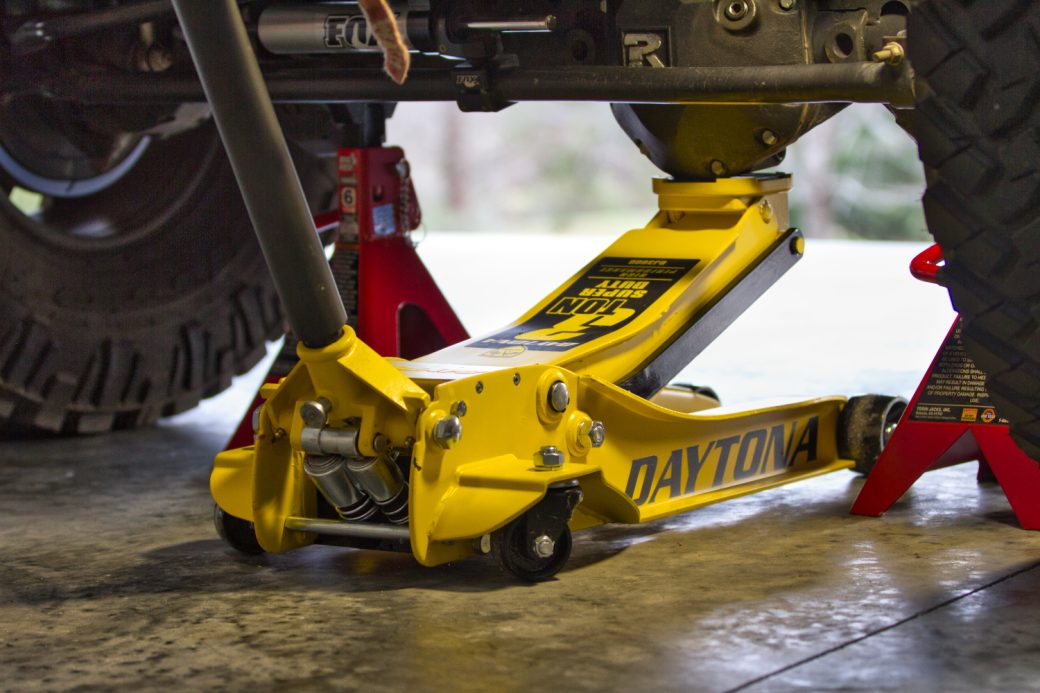

Place the floor jack on a hard level surface.

Craftsman professional floor jacks are extremely efficient devices that will lift and hold up to 4 tons in a safe and secure manner.

Failure to maintain factory specifications with regard to the oil level will cause premature failure of the jack or poor performance.

But a monthly check of the oil level in the master reservoir is a must.

Put the jack in the down position by opening the release valve the valve that when opened allows oil to flow back into the main oil reservoir located at the bottom of the jack thus lowering the ram piston.

Enjoy the videos and music you love upload original content and share it all with friends family and the world on youtube.

You should check your fluid level at least once every 12 months more often if you use the jack frequently like in a workshop situation.