It is most convenient to fill the car jack through a syringe smoothly filling the liquid consistency until it fills the entire volume of the tank and begins to flow out of the hole.

How to position floor jacks under load.

As a tip when working on a soft surface workspace such as an asphalt driveway we recommend that you place 1 4 or thicker mdfb medium density fiber board or plywood under the floor jack and jack stands to spread the weight of the vehicle over a larger footprint to avoid ruining the surface.

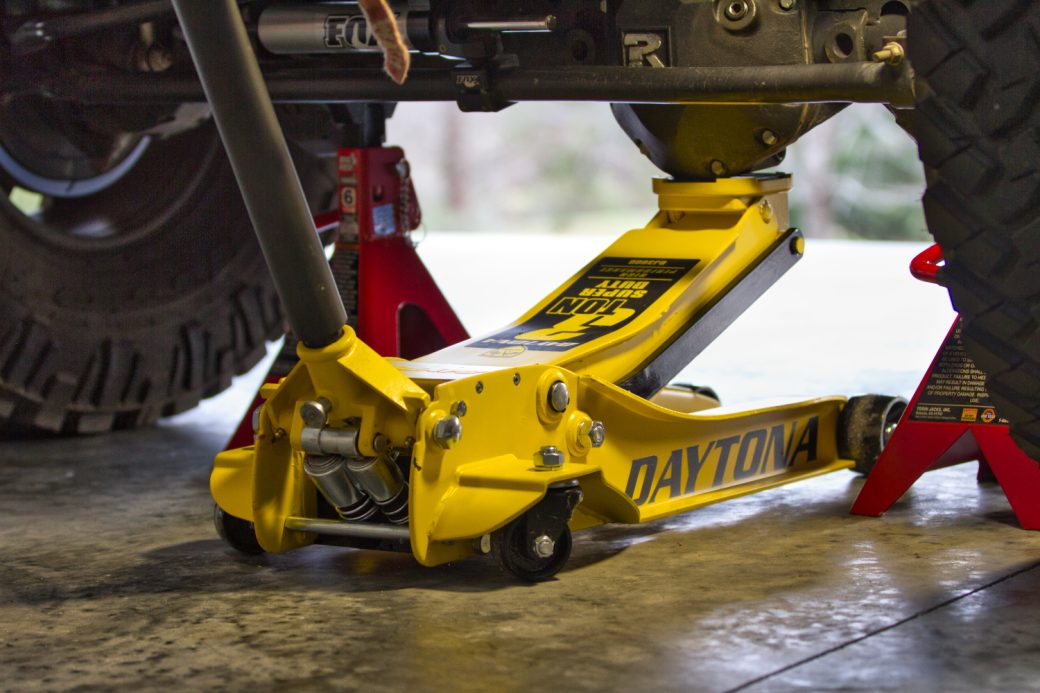

Line up the jack point to the flat part of the floor jack and start pumping the lever.

Lift the vehicle high enough for the necessary maintenance or repair job you need to accomplish.

Pump the handle a couple of times to lift the vehicle.

To bleed trapped air place the release valve in the fully retracted position counterclockwise of the handle remove the oil filler screw and pump the handle several times to purge the air from the system.

If the jack is a bottle while pouring it should be installed in the vertical operating position the rolling low profile floor jack is refueling in horizontal.

Position the floor jack under the jacking point.

There are a few easy cheap things you can do to bring a floor jack.

If you notice anything funny or you hear unusual sounds while jacking up the car release the valve the lower the vehicle and check again.

Do you have a hydraulic jack that is slow doesn t stay up or maybe doesn t lift at all.

A 2 ton jack can comfortably lift a mid range compact car.

Most we looked at were either 2 ton 3 ton or 3 5 ton jacks.

Exceeding stated limits is dangerous and most floor jacks have safeguards like relief valves so you can t do it.

This will raise the jack up to the jack point and begin lifting the vehicle.

Replace the oil fill screw and retest the floor jack.

Every floor jack has a maximum load capacity.